Neoloy® Tough-Cells Confinement Is Proven To Increase Modulus

Highway Engineering Modulus - Neoloy confinement increases the resilient modulus of confined granular materials in pavement structures

Neoloy Tough-Cell confinement increases the resilient modulus of confined granular materials in pavement structures, such as fine granular soils and recycled materials. The increase in the modulus (stiffness) of Neoloy reinforced base layers has been verified by modeling and numerical analyses by leading researchers around the world Kief and Rajagopal, 2011, Han et al 2010, Pokharel 2010, Meyer (2008). The increased modulus of the base course is defined as a Modulus Improvement Factor (MIF).

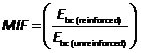

The MIF of the base layer relates to the improvement of the modulus of the base by Neoloy, as shown in the following formula:

and Ebc (unreinforced) = the modulus of the unreinforced base

Quantifiable metrics and calibration of the MIF (Modulus Improvement Factor) derived from Neoloy Tough-Cell testing enable integration of the MIF into the mechanistic-empirical design method for flexible pavements. This method is commonly used for highway engineering and design with Neoloy reinforced pavements. MIF values for Neoloy Tough-Cells ranges from 1.5 to 5.0 dependent on material of infill, subgrade and relative position of confined layer.

Benefits

- Reliable method for quantifying the Neoloy Tough-Cell contribution to the pavement structure

- Suitable for mechanistic-empirical methodology

- Recent research calibrated and integrated the use of Neoloy and MIF in road design methodologies

- Verified in multiple research projects and field demos

- Suitable for the design of unpaved and paved roads and railways

- The MIF value is dependent upon the material of infill, subgrade and location of reinforced layer