This published standard in the Netherlands is an excellent example of the growing trend to create standard guidelines for the use and design of geocells worldwide. It covers the required material properties and design principles that should be adopted to optimize geosynthetic reinforcement performance for pavements – and specifically for geocells.

This Guideline was written by a team of experts for SBRCURnet (CROW), a highly respected Dutch institute that develops guidelines and standards in the fields of civil engineering, road construction, and traffic engineering.

A key point of the document is that the extent of the reinforcing or stabilizing effect is determined by the material from which the geocell product is made and the geometry. The most important material properties are elastic stiffness and resistance to permanent deformation (creep). The limit on plastic deformation for reinforcement synthetics is defined as low deformation, e.g., less than 2%. The actual effectiveness of base reinforcement is reflected in the support improvement factor (SIF) and the modulus improvement factor (MIF).

The following sections are translated quotes from the Guideline for Determining the Improvement Factors and Design of Geocells in Road Building (SBRCURnet/CROW, NL):

“In addition to the structure of the road construction, the extent of the reinforcing or stabilising effect is determined by the material from which the product is made and the geometry. The most important material properties are the elastic stiffness and the resistance to permanent deformation (creep)…. Materials that exhibit a lot of creep will gradually lose their reinforcing capacity over time.”

“…Therefore, this type of base reinforcement is only effective if the deformations are limited to, for example, 0.5%. A distortion (elongation) of the geosynthetics of 2% horizontally will lead to many centimeters of distortion vertically in the road.

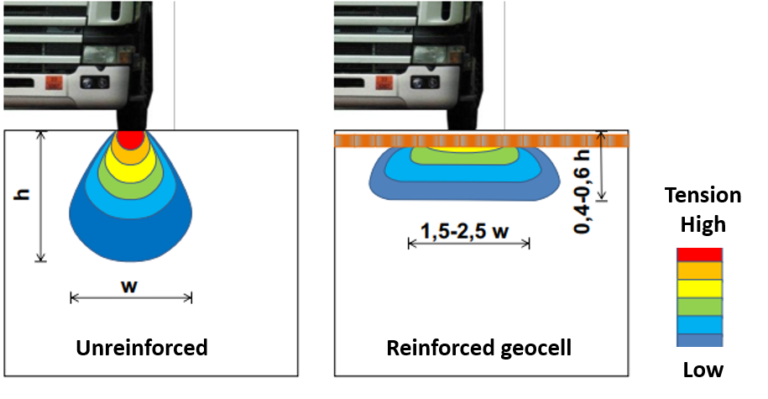

“The geocell mechanism provides an improved spread angle through the so-called “beam effect” (see Fig. 2-6).”

Property | Unit | Testing method | Value |

Dynamic stiffness modulus (net) (DMA-test) | MPa | EN-ISO 6721-1 ASTM E2254 | ** |

Cumulative plastic distortion (SIM test) | % m/m | ASTM D6992 | <3 |

Tensile force, non-perforated cell wall (wide width) | kN/m | EN-ISO 10319 | 20-29 |

Tensile force, perforated cell wall (wide width) | kN/m | EN-ISO 10319 | 16-25 |

UV and Oxidation resistance (High-Pressure Oxidative Induction Time (HPOIT) at 150°C | minutes | ASTM D5885 | > 400 |

* values available only for geocells with rigid cell walls

** values depend on the application