What is Neoloy?

Neoloy is a Novel Polymeric Alloy (NPA) developed to improve the strength and durability of geosynthetics’ products. It is a strong, stiff and sustainable alloy, and the only one in the UK’s market today that can guarantee geotechnical-engineering properties for up to 75 years.

Neoloy is commercially available to any geosynthetics manufacturer, interested in providing long-term warrantied performance to their products.

Why Neoloy Based Geocells?

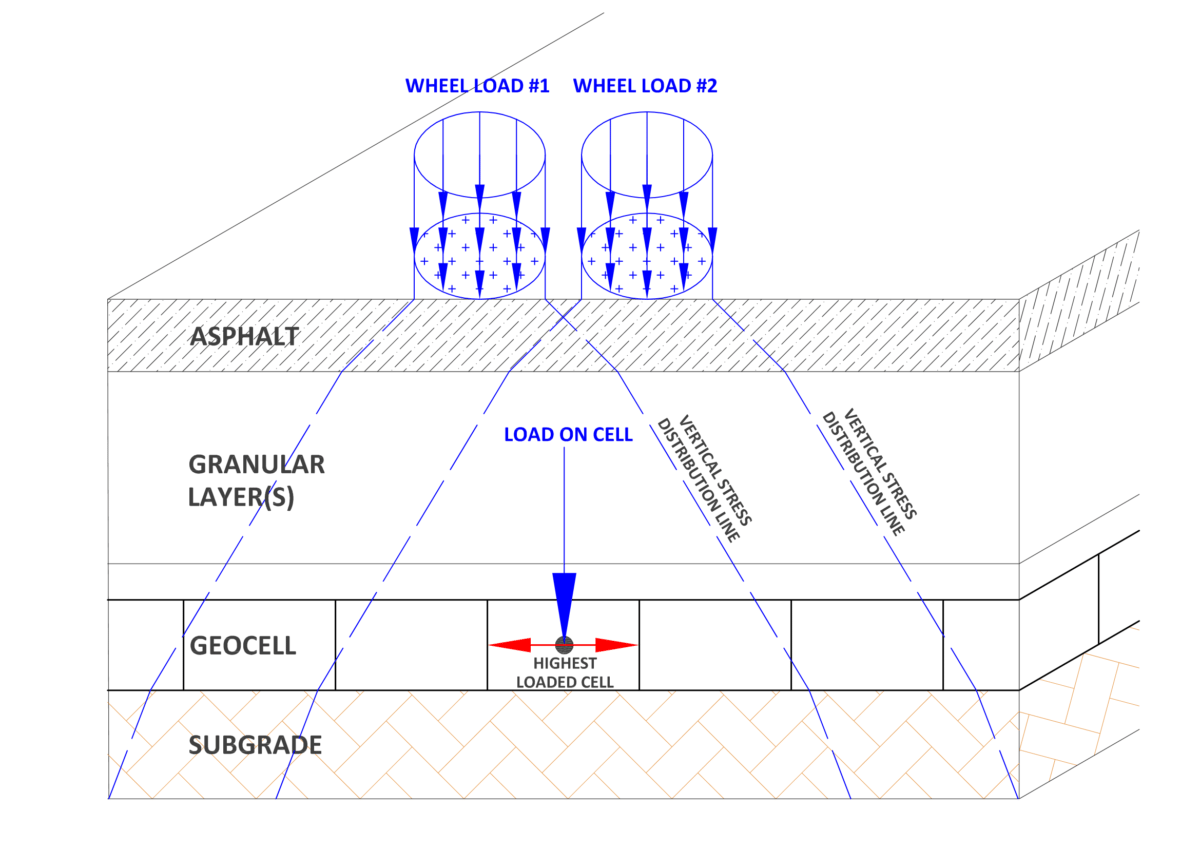

Geocells strengthen soft soil by mechanically confining the soil in three-dimensional honeycomb geometry. The geocell ability to confine soil over the long-term depends on retaining its geometry. If the geocell deforms over time such that its dimensions change, the infill soil may settle, compaction will be lost and the design’s parameters invalidated. Even a change of 3% in the geocell geometry may result in a structural failure.

For example, vertical loading on geocells in load support applications, such as roads, railways, airports and ports, is transferred laterally to hoop stresses on the cell walls (both cell strips and seams). This stress causes strains (deformations) which gradually accumulate over the project design life. If and when a geocell (polymer) creeps more than 3%, the enlarged geometry will result in a loss of soil confinement and the structure may fail.

The Neoloy material in the PRS Neoloy Geocell enables a new generation of geocell, with performance properties guaranteed for the project design life:

- Elastic Stiffness (Dynamic Modulus) – maintain stiffness under dynamic loading.

- Permanent Deformation (Creep) – elongation <3% at the end of the design life

- Cell Tensile Strength – maintain geocell geometry under load

Neoloy Geocells – Proven Results

More than 55 academic papers were published over the last 10 years validating the effectiveness of Neoloy (NPA) geocells used for soil reinforcement in roads, railways, retaining walls and other geo-technical engineering applications. As a result of this comprehensive research, Neoloy-based geocells are the only geocell with a proven engineering methodology that integrates the performance characteristics with the structural engineering requirements. Learn more about PRS Geotechnical Engineering Methodology.

In addition, Neoloy Geocells superior performance has been proven in 1000’s of projects worldwide. Testimonials from leading engineering firms and institutes attest to the fact that the Neoloy new generation of geocells are qualified for long-term, civil engineering use under any load conditions and environment.

Learn how Neoloy Geocells can help you meet your Project Requirements

- Very high creep resistance – enables long term design

- Predictable, long-term performance – unlike HDPE

- Very high tensile strength

- Durable under heavy duty dynamic loading

- Dimensional stability in thermal cycling

- Effective service range from-60°C to +60°C

- Very high creep resistance enables 75+ year design life

- High modulus geocell – suitable for use in base layer of asphalt pavements

- Enables substantial reduction in structural layers

- Specifications based on 3D performance parameters, not polymer or strip characteristics

- Outperforms any other HDPE geocell or geosynthetic

- High modulus PRS-Neoloy enables the use of marginal infill and reduction in layer thickness – lowers costs for every project.

- Increased pavement lifespan decreases project lifecycle costs

- Increase pavement lifespan– long term savings

- Lower construction costs – initial savings

- High strength material enables more cost effective geocell configurations